A Bottle Labeling Machine is a piece of industrial equipment that applies self-adhesive labels to bottles of various shapes and sizes. Once a bottle has been filled and capped, it is essentially a “blank” container. The labeling machine is what gives the product its face. It takes a roll of printed stickers and places them onto the glass or plastic surface with incredible speed and neatness. Without this machine, identifying what is inside a bottle would be a slow and difficult task.

As a dedicated Bottle Labeling Machine manufacturer, we know that a label does much more than just look good. In industries like medicine and food, the label is a legal requirement. It carries the “identity” of the product, including the brand name, the ingredients, and the barcode. If a label is missing or unreadable, the product cannot be sold. Our machines are designed to ensure that every bottle receives its label in the exact same spot, every single time.

Finding a reliable Bottle Labeling Machine supplier in India is essential for any business that wants to reach a global standard. These machines are built to handle the high-speed environment of a modern factory while maintaining extreme accuracy. By automating the labeling step, companies can track their products more easily using batch numbers and expiry dates printed directly on the label. This ensures safety and helps the business comply with international trade and health laws.

How the Machine Applies Labels: Step-by-Step

If you were to stand next to a labeling line, you would see a very organized and logical flow of movement:

- Infeed and Spacing: Bottles arrive from the capping machine on a conveyor belt. The machine uses a “spacer” or a “scroll” to create a specific gap between each bottle so they don’t bunch up.

- Detection and Positioning: As the bottle moves forward, an electronic sensor (a “photo-eye”) sees it. This tells the machine exactly when to release a label so it lands in the center of the bottle.

- Label Feeding and Separation: The label roll moves over a sharp “peeling plate.” The backing paper is pulled away at a sharp angle, causing the sticky label to pop off and wait for the bottle to pass by.

- Label Application: As the bottle touches the edge of the label, the machine uses a moving belt or a roller to wrap the label around the bottle’s body.

- Pressing and Smoothing: After the label is on, the bottle passes through a “pressing station.” A soft foam or rubber pad gently massages the label to squeeze out any air bubbles and ensure the edges are stuck down tight.

- Discharge: The finished bottle moves off the conveyor and into a collection tray or a packing box.

Key Technical Design Features

- Holding and Rotation Control: For round bottles, we use a “three-roller” system. This holds the bottle from three sides to make sure it doesn’t wobble while it spins, ensuring the label is perfectly straight.

- Dispensing Accuracy: Our machines use “stepper motors” or “servo motors.” These allow the machine to move the label roll in tiny, precise increments, so the label is never off-center.

- Sensor Intelligence: We use specialized sensors that can detect the gap between labels, even if the labels are transparent or have a shiny metallic finish.

- Speed Synchronization: The conveyor speed and the label dispenser speed are locked together. If the conveyor slows down, the labeler slows down, too, so the label always lands in the right spot.

Types of Bottle Labeling Machines

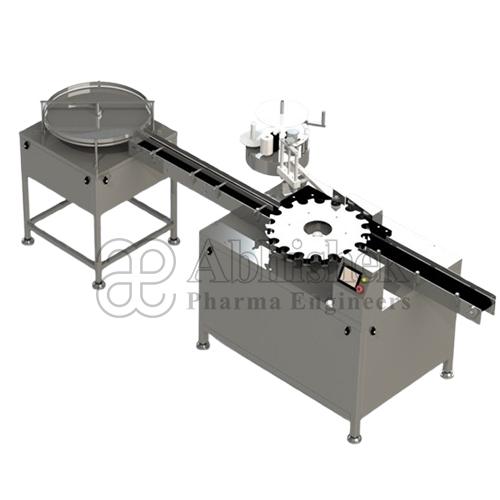

Wrap Around Bottle Labeling Machine

This is the most common machine for round bottles.

- How it works: The bottle spins in place while a label is fed to it, wrapping the sticker entirely around the curve.

- Best for: Water bottles, syrup bottles, and jars.

Front & Back Labeling Machine

This machine is designed for flat or oval-shaped bottles.

- How it works: It has two label dispensers—one on each side—to apply two separate labels at the exact same time.

- Best for: Shampoos, lotions, and dishwashing liquids.

Top Labeling Machine

This machine applies labels to the flat surface of a cap or a lid.

- How it works: The labeling head is positioned directly above the conveyor belt and “tamps” or blows the label onto the top of the bottle.

- Best for: Jars of jam or medicine containers that need information on the lid.

Multi-Side Labeling Machine

This is a highly advanced machine for square or rectangular containers.

- How it works: It can apply labels to three or four sides of a square bottle in a single pass through the machine.

- Best for: Motor oils, chemical jugs, and high-end cosmetic boxes.

General Technical Specifications

| Feature | Category |

| Bottle Shapes | Round, Flat, Oval, or Square |

| Label Size Range | Highly Flexible (Small to Large) |

| Label Roll Diameter | Standard Industrial Sizes |

| Speed Category | Medium to High-Speed Models |

| Material of Construction | Stainless Steel 304 or 316L |

| Automation Level | Fully Automatic / PLC Controlled |

| Power Usage | Standard Industrial Power |

| Maintenance Level | Low (Easy-clean design) |

Quality, Safety & Compliance

In a high-standard factory, a label must be more than just “on.” It must be perfect. Our machines follow GMP (Good Manufacturing Practice) standards. This means we focus on:

- Position Consistency: Ensuring every label is at the exact same height.

- Wrinkle Control: Using tension rollers to keep the label roll tight so no air is trapped.

- Readability: Ensuring the label is smooth so that scanners can easily read the barcodes and batch details.

Industry Applications

- Pharmaceuticals: Labeling syrup bottles, tablet jars, and oral drops with clear batch and expiry data.

- Food & Beverage: Putting brand labels on water bottles, juices, and sauces.

- Cosmetics: Labeling shampoos, creams, and perfumes with high-quality, attractive stickers.

- Chemicals: Applying warning labels and instruction stickers to cleaning products and pesticides.

Integration with the Packaging Line

A Bottle Labeling Machine is usually the final step in a three-part team:

- Bottle Filling Machine: Fills the bottle.

- Bottle Capping Machine: Seals the bottle.

- Bottle Labeling Machine: Identifies the bottle.

By connecting these machines together, you create a fully automatic system that requires very little human help.

Maintenance and Ease of Operation

We design our machines to be user-friendly for operators:

- Roll Changeover: Changing a label roll takes less than five minutes. The path for the labels is clearly marked on the machine frame.

- Size Adjustment: To change from a big bottle to a small one, you simply turn a few hand-knobs to move the guide rails and the sensor height. No tools are needed for most changes.

- Cleaning: The stainless steel body can be wiped down with a damp cloth to remove any dust or leftover adhesive from the label rolls.