This model exists for scientists and researchers. It is not meant to run all day at high speeds; instead, it is built for accuracy on a very small scale. If a lab is testing a new drug and only needs to fill 60 or 300 ampoules for a trial, the Ampoule Filling & Sealing Machine AFS-010 is the right tool. It gives the operator a lot of manual control to make sure every tiny detail is perfect before a medicine goes into big production.

Deep Comparison of Technical Concepts

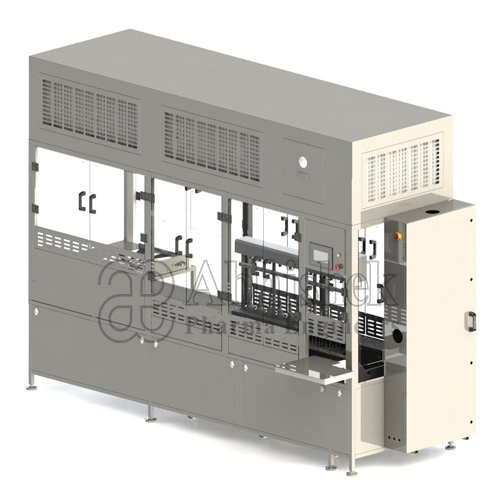

| Model | AFS-10 |

| No. of Head | Ten |

| Ampoule Handling Range | 1 ml to 10 ml |

| Production Output | Upto 15000 Ampoules/Hours |

| Filling Accuracy | ± 1% |

| Require Gas For Sealing | LPG & Oxygen (O₂) |

| Nitrogen Flushing | Pre-& Post Nitrogen Flushing Available |

| Power Specification | 5 H.P. |

| Electrical Characteristics | 440 Volts, Three Phase, 4 Wire System + Neutral |

| Contact Parts | Made from Stainless Steel 316L |

| Non Contact Parts | Made from Stainless Steel 304 |

| Overall Dimension | 3500mm (L) x 1200mm (W) x 1800mm (H) |