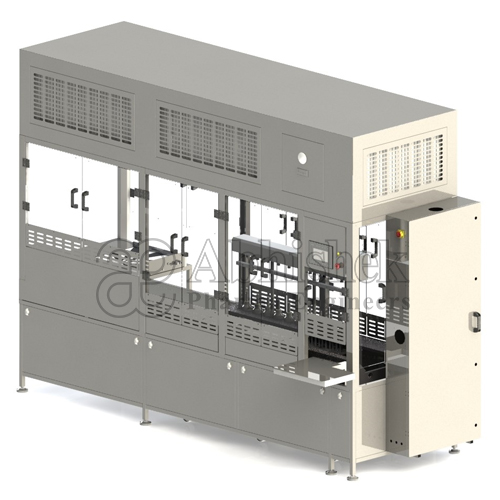

The Ampoule Filling & Sealing Machine AFS-350 is our fastest model, using a complex coordination of many filling and sealing heads. It is almost entirely automatic. It “thinks” ahead, checking for empty spots and managing gas pressure for a dozen flames at once.

This model is for global suppliers who need to produce millions of doses of vaccines or essential medicines as quickly as possible without sacrificing a single drop of quality.

Deep Comparison of Technical Concepts

| Model | AFS-350 |

| No. of Head | Twelve |

| Ampoule Handling Range | 1 ml to 10 ml |

| Production Output | Upto 18000 Ampoules/Hours |

| Filling Accuracy | ± 1% |

| Require Gas For Sealing | LPG & Oxygen (O₂) |

| Nitrogen Flushing | Pre-& Post Nitrogen Flushing Available |

| Power Specification | 5 H.P. |

| Electrical Characteristics | 440 Volts, Three Phase, 4 Wire System + Neutral |

| Contact Parts | Made from Stainless Steel 316L |

| Non Contact Parts | Made from Stainless Steel 304 |

| Overall Dimension | 4000mm (L) x 1200mm (W) x 1800mm (H) |