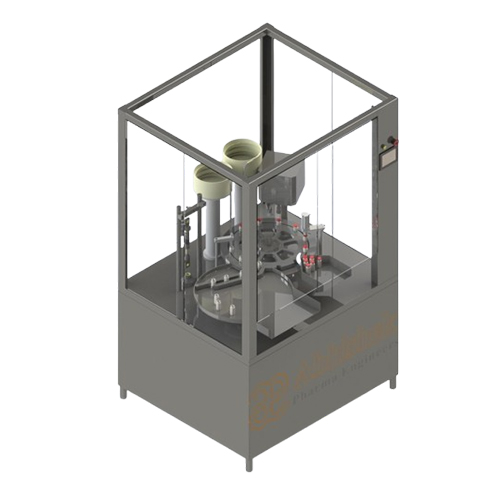

A Vial Filling, Stoppering & Capping Machine is a vital piece of equipment for modern medicine production. This all-in-one system handles the entire process of filling liquid into small glass bottles, known as vials. After filling, it carefully places a rubber stopper on top and seals it with an aluminum cap. This machine is designed to be fast, clean, and very precise, making it a favorite for pharmaceutical companies.

Using a Vial Filling Stoppering & Capping Machine helps factories stay safe and efficient. In the medical world, even a tiny mistake can be a big problem. This machine reduces human contact with the product, which keeps the liquid sterile and free from germs. It also speeds up the work, allowing labs and factories to produce thousands of vials every hour without wasting any expensive medicine.

Investing in this technology means your production line will be more reliable. The machine is built to follow strict health rules, ensuring every vial is filled to the exact same level. By combining three different jobs—filling, stoppering, and capping—into one unit, you save space in your factory and reduce the need for extra labor.

Working Process of the Vial Filling Stoppering & Capping Machine

The machine works in a smooth, continuous loop to ensure no time is wasted. Here is the simple step-by-step process:

Feeding: Empty vials are placed on a rotating turntable or a conveyor belt.

Filling: The vials move under nozzles that drop the exact amount of liquid into each one.

Stoppering: A vibrating bowl aligns rubber stoppers, and the machine picks them up to place them on the filled vials.

Capping: Aluminum caps are placed over the stoppers.

Sealing: A special tool spins and presses the cap to create a permanent, leak-proof seal.

Discharge: The finished vials move to the end of the line for labeling and packing.

What is a Vial Filling Stoppering & Capping Machine?

A Vial Filling Stoppering & Capping Machine is an automated system used to package liquid drugs. It starts by moving empty, clean vials along a conveyor belt. The machine then fills them with a specific amount of liquid. Once filled, a rubber stopper is pressed into the neck of the vial to keep the air out.

Finally, the machine adds a metal cap and crimps it tightly. This ensures the medicine stays safe until a doctor or nurse is ready to use it. Because it does everything in a controlled environment, it is the best way to package vaccines, antibiotics, and other injectable fluids.

Technical Specifications

| Feature | Specification |

| Filling Range | 2ml to 100ml |

| Output Speed | 30 to 120 vials per minute |

| Number of Heads | 2, 4, or 6 (Customizable) |

| Power Supply | 220V / 415V, Three Phase |

| Machine Construction | Stainless Steel 304/316 |

| Stoppering Type | Partial or Full Vacuum Stoppering |

| Capping Type | Roll-on Pilfer Proof (ROPP) or Flip-off |

| Control System | PLC with Touch Screen (HMI) |

Key Features of Vial Filling Stoppering & Capping Machine

- Stainless Steel Body: Built with high-quality SS 316 and SS 304 to prevent rust and meet health standards.

- No Vial, No Fill System: Sensors detect if a vial is missing so the machine doesn’t waste liquid.

- Easy Controls: Features a simple touch-screen panel that anyone can learn to use quickly.

- Adjustable Speed: You can make the machine go faster or slower depending on your needs.

- Compact Design: Takes up less floor space compared to three separate machines.

- High Accuracy: Filling pumps ensure that every vial gets the right amount of medicine every time.

Benefits for Pharma Manufacturers

Using a Vial Filling Stoppering & Capping Machine offers several advantages for your business:

- Better Hygiene: Less human touch means less chance of contamination.

- Cost Savings: Reduces the amount of wasted product and lowers labor costs.

- Consistency: Every batch of medicine looks and performs exactly the same.

- Scalability: Perfect for small labs that want to grow into large-scale factories.

- Compliance: Helps your facility meet international “Good Manufacturing Practice” (GMP) standards.

Frequently Asked Questions

It is used to fill liquid medicine into vials, plug them with rubber stoppers, and seal them with metal caps to keep them sterile.

Yes. The machine is made of stainless steel and is designed to work inside sterile environments to prevent germs.

Most machines can handle vials from 2ml up to 100ml. You can easily adjust the settings for different sizes.

Absolutely. It is designed with smooth surfaces and easy-to-remove parts, making it simple to wash and sanitize between batches.

Yes, we can change the number of filling heads or the type of capping tool to match your specific production goals.

Yes, it has smart sensors. If there is no vial on the belt, the machine will not drop any liquid or stoppers.