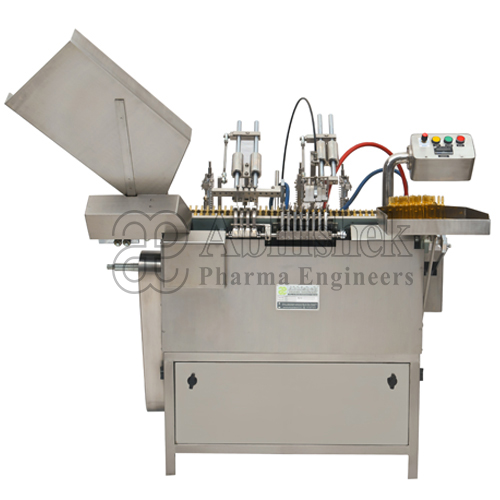

The Ampoule Filling & Sealing Machine AFS-100 is the “middle ground” model. It is designed to work in standard eight-hour shifts, balancing speed with very high filling accuracy. It is a common sight in Indian pharmaceutical plants because it is reliable and easy to fix.

It handles the most common ampoule sizes with very little downtime for cleaning or changing parts.

Deep Comparison of Technical Concepts

| Model | AFS-100 |

| No. of Head | Four |

| Ampoule Handling Range | 1 ml to 5 ml |

| Production Output | Upto 5000 Ampoules/Hours |

| Filling Accuracy | ± 1% |

| Require Gas For Sealing | LPG & Oxygen (O₂) |

| Nitrogen Flushing | Pre-& Post Nitrogen Flushing Available |

| Power Specification | 1 H.P. |

| Electrical Characteristics | 230 Volts, Single Phase, 4 Wire System |

| Contact Parts | Made from Stainless Steel 316L |

| Non Contact Parts | Made from Stainless Steel 304 |

| Overall Dimension | 1100mm (L) x 1100mm (W) x 1000mm (H) |