The Journey from Liquid to Life-Saving Dose

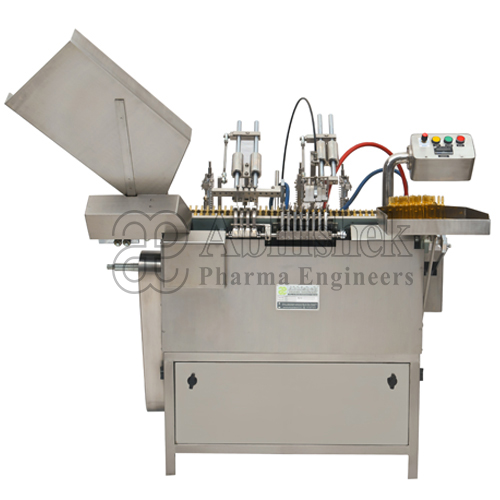

An Ampoule Filling & Sealing Machine is a specialized piece of equipment designed to perform a very delicate task: putting exactly the right amount of liquid medicine into a glass bottle and closing it forever. Imagine a row of tiny glass tubes moving through a machine. Each one must be handled gently so it doesn’t break, filled perfectly so no medicine is wasted, and melted shut so no air can get inside. This process turns a simple piece of glass and a tank of medicine into a safe, sterile product ready for a doctor to use.

When you think about how an Ampoule Filling & Sealing Machine manufacturer builds these units, you realize it is all about timing. The liquid medicine moves from a storage tank through thin tubes. At the exact moment an ampoule stops under a needle, the pump pushes the liquid out. Then, the needle must pull back quickly without leaving a single drop on the neck of the glass. If the neck gets wet, the seal won’t work later. This balance of movement and stopping is what makes the machine so impressive.

After the liquid is inside, the machine doesn’t just put a cap on the bottle. Instead, it uses a hot flame to melt the glass itself. As a trusted Ampoule Filling & Sealing Machine supplier in India, we ensure our machines manage this heat perfectly. If the flame is too cold, the glass won’t melt; if it’s too hot, the glass might shatter or the medicine inside might get ruined by the heat. The machine must hold the ampoule, spin it or move it through the fire, and then pinch the top shut to create an airtight dome.

How the Machine Works: A Simple Logic

If you were standing in front of the machine for the first time, here is the logic of how it “thinks” and moves:

- The Entry: Ampoules arrive in a line. The machine uses a “walking beam” or a star wheel to pick them up one by one. It acts like a careful hand, making sure they stay upright and spaced apart.

- The Perfect Hold: The machine stops the ampoules at a specific “station.” It holds them firmly so they don’t shake. This is important because the filling needles are very thin and must go exactly into the center of the glass neck.

- The Measured Dose: A pump moves. It calculates the liquid based on how far the piston travels. It squirts the medicine into the bottom of the ampoule. To keep the medicine fresh, the machine often blows a little nitrogen gas inside to push out the oxygen.

- The Final Melt: The ampoule moves into a row of blue flames. As the glass gets soft and glows orange, a mechanical gripper grabs the very top of the neck and pulls it upward. The melted glass stretches and snaps shut, sealing the medicine inside a glass bubble.

How to Choose the Right Model

Selecting a machine is a practical decision based on your daily life in the factory:

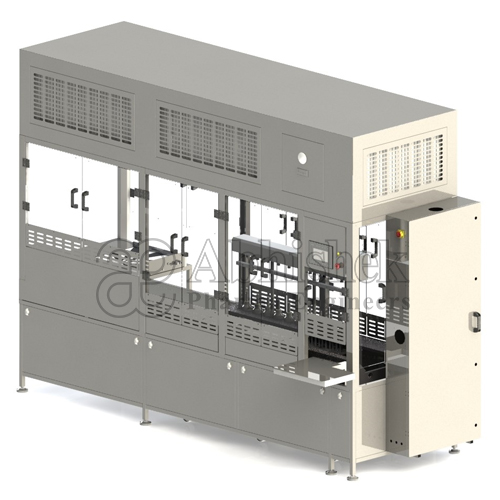

- Think about your volume: If you only have 5,000 ampoules to fill a week, a high-speed AFS-350 would be a waste of energy. A smaller model like the AFS-30 is better.

- Think about your shift: If you plan to run the machine for 16 hours a day, you need a heavy-duty model like the AFS-150 that can handle the heat of long-term running.

- Space and Skill: Smaller models fit in a corner and are easy for a new operator to learn. The larger, faster machines need more floor space and a technician who understands computer-controlled systems.

Where These Machines Work

Our machines are essential in several specialized areas:

- Injectable Medicines: For vaccines and emergency room drugs.

- Sterile Liquids: For any medicine that cannot have preservatives and must stay pure.

- Veterinary and Biotech: For animal health products and advanced scientific medicines that are very expensive and cannot be wasted.

- Pesticide & Agriculture Firms: For accurate filling and secure sealing of liquid formulations, ensuring safe packaging and consistent dosage.

- Cosmetic industry: For hygienic and precise filling of serums, oils, and liquid beauty products.

Quality and Process Discipline

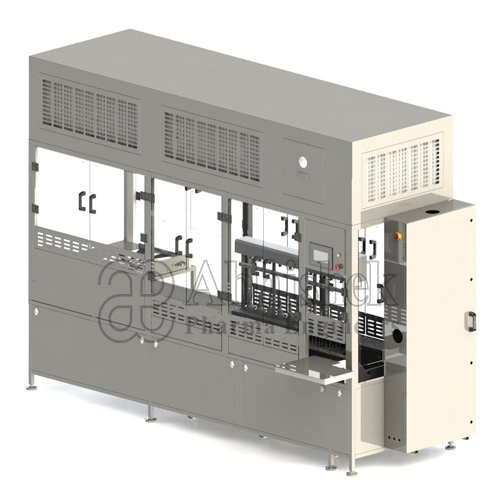

As an Ampoule Filling & Sealing Machine manufacturer, we follow “Good Manufacturing Practice” (GMP) rules. This means we build machines that are easy to clean so that no bacteria can grow in the corners. We use high-grade stainless steel that doesn’t react with the medicine.

Our goal is “process discipline”—making sure the machine does the exact same thing every single time. From the way the needle enters the glass to the temperature of the sealing flame, everything is set up to be consistent. This consistency is what keeps patients safe and ensures that every ampoule leaving your factory is a perfect, life-saving dose.