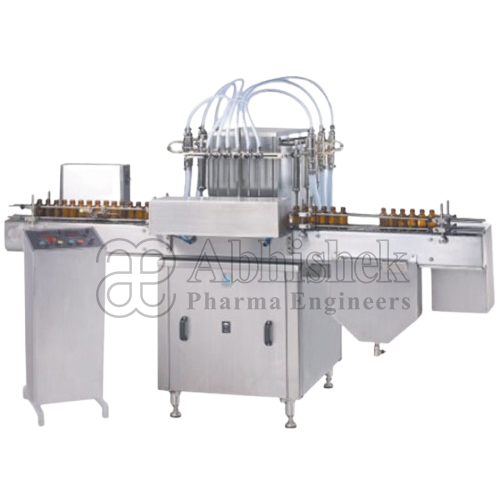

A Bottle Filling Machine is a piece of industrial equipment designed to pour liquids into bottles with extreme precision. Think of it as a highly advanced kitchen funnel that never spills and knows exactly when to stop. In a factory setting, filling thousands of bottles by hand would be impossible and messy. This machine automates that task, ensuring that every bottle—whether it contains medicine, juice, or shampoo—gets the exact same amount of liquid every single time.

As a dedicated Bottle Filling Machine manufacturer, we focus on the science of flow. When liquid moves from a large tank into a narrow bottle, many things can go wrong. The liquid might foam up, it might drip after the bottle moves, or it might splash. A well-designed machine controls the speed and pressure of the liquid to prevent these issues. This ensures that the production line remains clean and that no expensive product is wasted on the floor.

Finding a reliable Bottle Filling Machine supplier in India is a vital step for any business that wants to grow. These machines help industries maintain high hygiene standards by keeping the liquid in a closed system, away from human contact. This is especially important for pharmaceutical and food products where safety is the top priority. A smooth-running filling machine is the heartbeat of a successful packaging line, turning empty containers into finished products ready for the shelf.

How the Machine Operates: Step-by-Step

If you were to watch the machine work, you would see a very organized and logical flow of movement:

- Infeed and Spacing: Empty bottles arrive on a conveyor belt. The machine uses a “spacer” (like a rotating screw or a gate) to make sure there is enough room between each bottle so they don’t crash into each other.

- Holding and Alignment: Sensors “see” the bottles and stop them exactly under the filling nozzles. Mechanical “fingers” or guides hold the bottles firmly so they stay perfectly centered.

- The Fill: The filling nozzles lower into the necks of the bottles. The liquid is released into the bottles based on a specific method (like a timer or a pump).

- Flow Control and Cut-off: Once the correct amount is reached, the machine instantly cuts off the flow. Some machines use a “suck-back” feature to pull a tiny bit of liquid back into the nozzle to prevent a final drip.

- Discharge: The nozzles rise, the guides release the bottles, and the conveyor moves them forward to the capping and labeling machines.

Key Technical Design Features

- Nozzle Design: Nozzles are made to fit the neck of your bottle perfectly. “Bottom-up” nozzles start at the bottom of the bottle and rise as they fill to prevent bubbles and foam.

- Drip Prevention Logic: We use special valves and vacuum systems to ensure that when the machine says “stop,” the liquid stops immediately with zero mess.

- Size Changeover: Our machines use “no-tool” adjustments. This means an operator can turn a few knobs to change the machine’s height and width to fit a new bottle size in minutes.

- Stability: The machines are built on heavy stainless steel frames to prevent shaking, which keeps the filling needles steady and precise.

Types of Bottle Filling Machines

Gravity Bottle Filling Machine

This is the simplest type of machine. The liquid tank is held above the bottles, and gravity pulls the liquid down. It uses a timed valve to control the fill.

- Best for: Thin, watery liquids like vinegar or window cleaner.

- Accuracy: Good for basic needs, but not for thick liquids.

Overflow Bottle Filling Machine

This machine is unique because it fills every bottle to the exact same visual height, even if the bottles themselves are slightly different sizes. It pumps more liquid than needed, and the “overflow” is sucked back into the main tank.

- Best for: Clear bottles where the customer expects to see a perfectly even line of liquid across the shelf.

- Liquid types: Thin to medium thickness, including foamy liquids.

Volumetric Bottle Filling Machine

This machine measures a specific “volume” of liquid in a chamber before pushing it into the bottle. It works like a measuring cup.

- Best for: Expensive liquids where you cannot afford to waste a single drop.

- Accuracy: Very high.

Piston Bottle Filling Machine

Imagine a large syringe. A piston pulls a measured amount of liquid into a cylinder and then pushes it out into the bottle.

- Best for: Thick, chunky, or heavy liquids like honey, sauces, or thick creams.

- Accuracy: Excellent for high-viscosity products.

General Technical Specifications

| Feature | Specification Category |

| Bottle Sizes | Wide Range (50ml to 5 Liters) |

| Filling Volume | Highly Adjustable |

| Filling Heads | 2, 4, 6, 8, or 12 Heads |

| Filling Speed | Low to High Speed Options |

| Material | Stainless Steel 304 or 316L |

| Automation | Semi-Automatic to Fully Automatic |

| Power Needs | Standard Industrial Power |

| Air Requirements | Needed for Pneumatic Models |

| Maintenance | Low (Easy-clean design) |

Quality, Hygiene & Compliance

In a professional filling environment, cleanliness is everything. Our machines are built following GMP (Good Manufacturing Practice) standards. This means we use smooth surfaces and high-grade stainless steel that doesn’t react with chemicals and is easy to disinfect. We focus on spill control to keep your floors dry and your bottles clean, ensuring that your final product meets all health and safety regulations.

Industry Applications

- Pharmaceuticals: Syrups, liquid medicines, and oral drops.

- Food & Beverage: Water, juices, oils, and sauces.

- Cosmetics: Shampoos, lotions, and perfumes.

- Chemicals: Cleaning agents, pesticides, and liquid fertilizers.

Integration with the Packaging Line

A Bottle Filling Machine is usually part of a team. It connects smoothly with:

- Bottle Washing Machines: To clean the dust out before filling.

- Capping Machines: To seal the bottle immediately after it is filled.

- Labeling Machines: To add the brand name and batch details.

- Packing Systems: To put the finished bottles into boxes for shipping.

Maintenance and Operational Ease

We design our machines to be operator-friendly. Daily cleaning is simple because the liquid paths can be flushed out quickly (this is often called “Clean-in-Place” or CIP). The controls are easy to understand, usually featuring a touchscreen that shows the machine’s status. With regular check-ups on the seals and valves, these machines are built to run for many years without trouble.